FAQs About Steel Flashings

Steel roof and wall flashings are vital components helping to protect your building against water and wind intrusion.

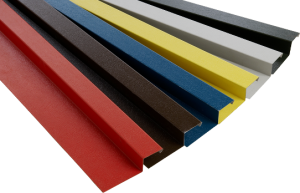

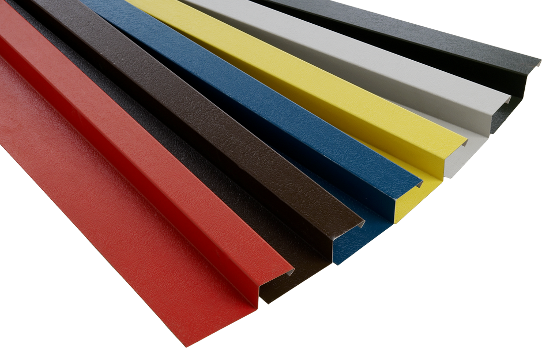

They can also be used architecturally to enhance the aesthetics of the building, offering contrasting colours to the profiled roof and wall sheets.

At South East Fabricators Ltd (SEFAB), we manufacture flashings in a range of colours and finishes to your specific requirements.

Q: What Are Steel Flashings Used For?

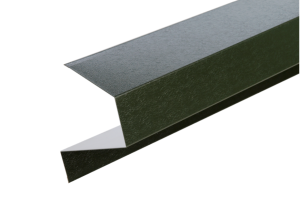

A: Made from galvanised steel, flashings are typically used on commercial, industrial and agricultural steel-clad buildings. They are used to seal the perimeter of the buildings to divert water away from openings, thus preventing water penetration and seepage.

There are many types of flashings, but the following are the most common:

Roof/Ridge Flashing

Eaves Flashing

Corner/Barge Flashing

Drip Flashing

Abutment Flashing

Valley Flashing

Sill Flashing

Q: SEFAB’s Flashings.

A: We manufacture most of our flashings in 3m lengths as standard and can be produced in a huge range of colours and finishes.

We hold large stocks of steel flat sheet ready for immediate processing into flashings. Our stocks include, but are not limited to:

Leathergrain (Plastisol) coated

HPS200 Ultra

Polyester coated

Prisma/Granite HDX coated

White Liner/Enamel

Mill Finish

We also hold a limited range of 4m long sheets in stock. Please contact us for details.

Q: Bespoke Flashings?

A: The shape and size of flashings are almost limitless, and therefore, all of our flashings are made to order to the customer’s specific design.

Call us on 01342 337200, and our friendly sales team will talk you through your requirements and advise on the best solution for you.

Q: Why use Steel Flashings?

A: One of the advantages of using steel for your flashings is its durability and weather resistance. The steel sheet is known for its strength and is extremely durable, therefore, making it ideal for forming into flashings.

The different coatings/finishes applied to the steel provide excellent corrosion and abrasion resistance, enhancing the lifespan of the material.

Q: Are Steel Flashings Suitable for Coastal Areas?

A: Due to the corrosive nature of the salt air in coastal areas, no product will have the same lifetime as those located some distance inland.

Therefore, different coatings offer different lifetimes, and therefore, please contact our sales team for advice on the specific coating to meet your requirements.

Carrying out regular maintenance and cleaning of the flashings will also prolong the lifespan of the material.

Q: What Maintenance is Required for Steel Flashings?

A: The flashings require minimal maintenance. They should be cleaned periodically, thereby removing any debris which could lead to corrosion.

If any issues are identified, prompt repairs or re-coating can extend their service life. Proper maintenance can help preserve their appearance and functionality.

Q: How quickly can SEFAB manufacture the flashings??

A: Our standard turnaround for flashings is five working days. However, therefore, we are able to accommodate 24 and 48-hour turnarounds subject to prior notice and our workload at the time of order.

Q: I’m not sure exactly what flashings I need?

A: If you require any further information or advice, then please call our friendly sales team on 01342 337200, who will talk through your project and options.

1 comment

Join the conversationRaymond Clark - January 1, 2024

What if any is the expansion rating in hot weather, is there a risk of failure due expansion